Compostable Packaging

We are strongly advocating the use of sustainable packaging. Our drive relies on reducing our reliance on traditional fossil fuel based products that would otherwise end up in landfill. We are internationally certified with ABA and TUV Home Compostable accreditation for our end packaging product, unlike our competitors that either have some accreditation for some of their components or none at all!

Certified Home Compostable Barrier Packaging

Sustainable

Our Home Compostable Packaging is made from renewable resources such as plant fibres.

What is Home Compostable Packaging?

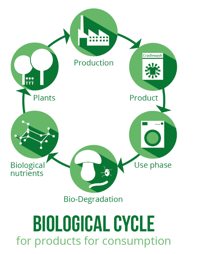

Compostable films are biodegradable materials that break down naturally and return nutrients back into the soil under specific composting conditions

TUV OK Home Compost

Materials in our packaging

Our home compostable packaging is derived from a range of natural products such as paper, eucalyptus fibre and cassava and corn starch.

Search below on some FAQ.

Sustainable – Our compostable packaging is made from renewable resources such as plant fibres, reducing the reliance on petrochemicals.

Cradle to Cradle – Packaging that can be returned back to nature after use.

Waste reduction – Designed to replace multi-layer barrier laminates that can’t be or aren’t being recycled.

Our products are ideally suited to dry goods up to 1kg in weight (grade dependant) that require barrier against oxygen and moisture. They have a natural barrier to aroma, oils (including mineral oils) and grease.

Oxo-degradable products are still sourced from fossil fuel based resources, they will also take a significantly longer time to break down I comparsion to Compostable Bio-plastics. Unfortunately there has not been conclusive evidence for the complete breakdown of oxo-degradable plastics or the types of residual compounds released in this process. Where as certified compostable products have gone under this rigorous testing.

There are currently 150 organic recycling or Industrial Composting facilities in Australia. While not all households in Australia are provided kerbside collection of organic waste, we are advocating the use of our certified home compostable alternatives.

This will be dependent on what structure is being replaced but typically they are 2 – 3 times more expensive than traditional petrochemical packaging. This is mainly down to the low price of oil based plastics and economy of scale.

Compostable products when organically recycled are a true cradle to cradle solution.

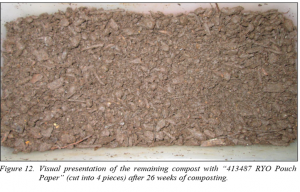

Our laminates are independently tested and accredited to prove they breakdown at set composting conditions and are checked for eco-toxicity to ensure that they have no negative impact on the composting environment.

We do not use materials that have intentionally added GM content.

Our compostable packaging is organically recyclable and is a viable alternative to Petrochemical based plastic packaging that isn’t being recycled.

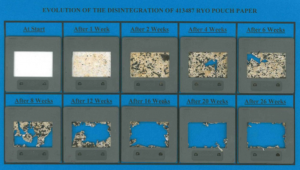

Home composting – less than 26 Weeks at ambient temperature (< 30c)

Industrial composting – Less than 12 Weeks at 60c

Whilst recycling, anaerobic digestion, composting and incineration create value from waste, landfill has no value and is not a sustainable option in the future. Compostable packaging will react in landfill the same as other organic waste such as paper and wood. Research has been undertaken which shows that organic waste in deep landfill is inert due the lack of oxygen and moisture required to start bio-degradation. * Environment and Plastics Industry Council Canada

No packaging should be littered but unlike Petrochemical based plastics our home compostable packaging will start to biodegrade in the presence of microbes, moisture and oxygen at ambient temperatures.

8 million tonnes of plastic ends up in the oceans each year and by “2050 there’ll be more plastic in the sea than fish…” (Source: Ellen McArthur foundation – New Plastics Economy)

Packaging either petrochemical based or bio-based is not and should not be designed to be littered but as the figures above show it is happening.

We are independently testing our home compostable laminates in a marine environment (ASTM D7081) and we are seeing encouraging results regarding biodegradation. Our laminates are designed to break down at ambient temperature in the presence of microbes, water and oxygen and naturally biodegrade back into water, Co2 and biomass without eco-toxicity.

24 weeks immersed in sea water

24 weeks immersed in sea water